Types of Cedar Siding for Sale

Cedar Varieties: Western Red Cedar, Inland Red Cedar, California Incense Cedar, Alaskan Yellow Cedar, and Sugi Cedar (Finger jointed only).

Cedar Siding Grades: Clear, Clear Finger Joint, Near Clear, Mill Select STK, Customer Select.

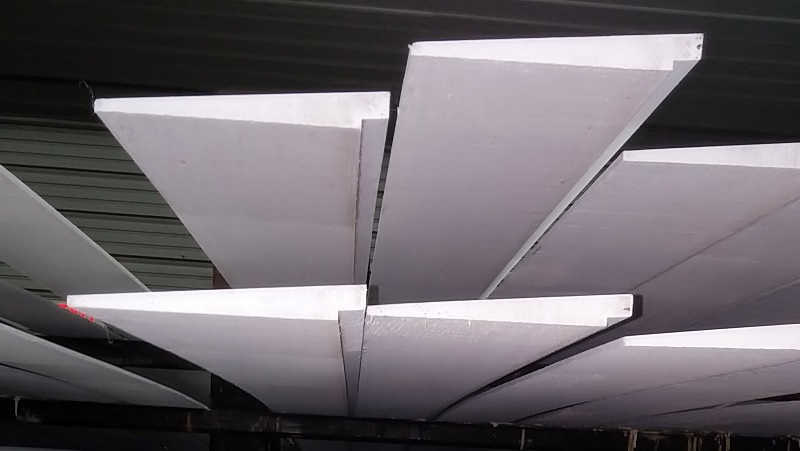

Cedar Siding Patterns: Cedar shiplap, cedar lap siding, cedar dutch lap siding, tongue and groove cedar siding, bevel cedar siding, clapboard cedar siding, channel rustic lap siding, wavy edge siding.

Cedar Siding Finish: Primed, painted, stained, or unfinished.

Cedar Siding Texture: Smooth face, Rough face.

How to Order Cedar Siding with Buffalo Lumber

Get in touch with us via email at sales@buffalolumber.com, or call us at 877-960-9663, or fill out our contact form here.

All Buffalo Lumber orders are delivered MILL DIRECT to your JOB SITE. Our orders are custom milled and factory finished. All communication is handled personally - by phone and email.

Our normal lead time from order to door is 2 - 8 weeks.

Once your order is placed, we stay in email and phone contact with you throughout the course of your order. Your salesman will be available to answer any questions you may have along the way. Delays, though unlikely, do happen and you'll be the first to know if that's the case. Buffalo Lumber takes pride in our products and customer service and we are committed to making sure your wood and experience with Buffalo Lumber is the best in the industry...from forest to front door.

We can help you plan your project. We will get your order in the queue so it is ready when you are.

Shedding Some Light on Decisions that Affect your Budget

Cedar Siding Grades

CLEAR CEDAR SIDING vs. KNOTTY: The most significant question is "Do you like knots?". Knotty wood costs half as much as Clear. If you don't want knots you will pay TWICE AS MUCH. How do you like Knots now?

Cedar Siding Size & Pattern

We can mill almost any size 1X6, 1X8, 1X10 and pattern you want - SHIPLAP, NICKEL GAP, DUTCH LAP, TONGUE & GROOVE, CHANNEL RUSTIC, BEVEL, CLAPBOARD, LOG AND WAVY EDGE. You should know that any size over 1x8" is prone to cupping while smaller sizes require more labor to install. Certain patterns like Bevel can be less expensive than T&G or Ship-Lap because the specific mill cut makes better use of the original board.

Cedar Siding Finish - Prime, Paint, Stain

WARNING: You HAVE to coat ALL sides and edges prior to installation to ensure against ROT. Having your cedar siding Pre-Finished at the mill will be approximately 50% less expensive than on-site finishing.. Opacity determines the longevity of your finish. Figure 1-2 years with Transparent finish, 2-5 with Semi-transparent, 4-7 with Semi-solid, 7-10 with solid and up to 25 years with primer and paint.