A FACTORY FINISH ensures a lasting, higher quality job than traditional "on site" stain or prime applications. Factory finishing costs about half the amount of field staining. Pre-finishing your cedar siding eliminates the problems of lap marks, shrinklines, streaking, color variation, and job site dirt pick-up.

All four sides of the board, are completely sealed, ensuring total protection. Controlled temperature and humidity levels stabilize any moisture in the wood.

The finished siding arrives at the job site totally protected from exposure to water and sunlight. Western Wood Products Association and the California Redwood Association recommend pre-finishing all wood siding including cedar!

If your selected pattern has one smooth side and one rough side, be sure to tell us which face you plan to expose. The pre-finisher will place the wet finished boards on the drying rack with your exposed face up so it does not dry with rack marks. Cedar is a durable wood, but leaving it untreated is not recommended since finishing will greatly increase it's service life.

Some darker oil-based stains can take a LONG TIME to dry. In fact our mills complain when our customers order semi-solid stains. Do YOU have the SETUP and the time to WAIT for miles of boards to dry?

FACT - The first thing the Western Red Cedar Lumber Association will tell you is that all cedar siding needs to be sealed on all six sides prior to installation and then re coated as needed on the face for the lifetime of the wood.

"FINISH SIDING PRIOR TO INSTALLATION - Before installation (job site), applying a finish to all surfaces (including ends) is recommended. Factory applied finishes are best. They ensure the best performance of the finish.

The type of coating will be determined by final finish and look selected. The finish protects the wood from moisture absorption and UV degradation, helps prevent staining caused by mildew and extractives and will increase the service life of top coats." from WRCLA How to Install Western Red Cedar Siding.

We interviewed Brandon Stendal- owner of Stone Valley Painting, LLC. and a customer of ours and asked-

"What is the value of factory finish?"

"Usually we are only finishing the face of the building. For us- a commercial painter- to prime coat 6 sides in the field takes about twice as long as coating the face alone after installation. We charge $50 hour commercially so the price immediately doubles.

We primed all 4 sides of about 833 sqft of your wood siding and it took 2 guys about 8 hours to do this job. It took 5 gallons of primer to coat it (between $25 and $30 per gallon) and we had to rack it at our own warehouse and then transport to the jobsite.

I would actually prefer my customers to get a factory finished primer coat and then have me do the final coat in the field- that is the best wood siding performance option.

That may not sound like it is good for business but long term, happy customers are my business!"

We agree completely.

1x6 CLEAR Cedar Shiplap "Nickel GAP" profile - Mill Pre-Stained TWP Natural #1530 – home in NJ

1x6 CLEAR Cedar Shiplap "Nickel GAP" profile - Mill Pre-Stained TWP Natural #1530 – home in NJ

Factory finishing coats 4 of six sides - You get the face, the back and both side edges, the butt ends need to be sealed when installed on the jobsite.

If you are going to do the job right- you can't do it better (or cheaper) than the machines. If you are planning to stain instead of paint- the number of gallons needed per square foot virtually doubles. You do not have to apply a final coat to the face after installation but you had better have a large, well ventilated area with racks for the wood siding to dry - usually 3-7 days depending on humidity and finish choice.

The fact is that sealing the wood on all six sides prior to installation is the single most important thing you can do to ensure the long term performance of your wood siding- factory finishing saves the headache factor (literally) and is the first step to doing the job right.

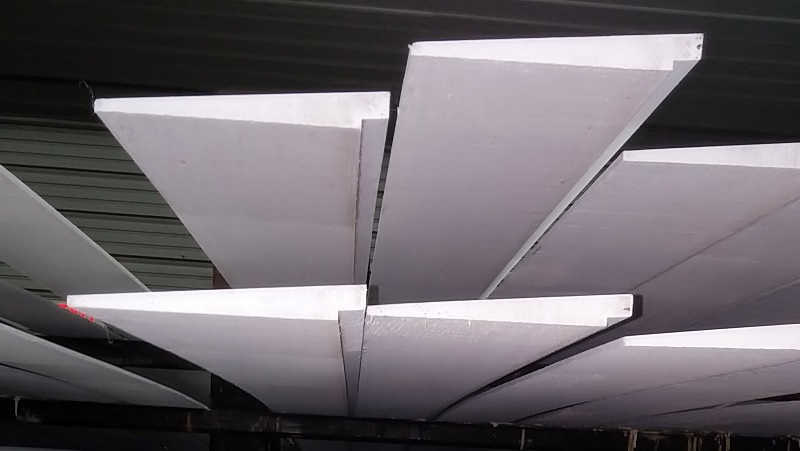

Factory Primed CLEAR Finger Joint Bevel Siding Racked to Dry

Factory Primed CLEAR Finger Joint Bevel Siding Racked to Dry

The truth may not be what you "want" to hear but remember if it's worthwhile to do:

It costs 3 times as much and takes 3 times as long as you originally thought it would.

It costs 10 times as much to fix a screw up as to do things right in the first place!

The Question Is - Can You afford Not to Factory Finish?